Products

For over 50 years, we have developed solutions to manage motion and minimize resulting noise, vibration and shock.

We are looking forward to working with you and solving any challenge you may encounter.

If we don’t have an existing answer to your specific needs we shall work with you and create one from scratch.

| Products | Part # | Description |

|---|---|---|

| Cushion Commector | For compression loads up to 13.3 lbs. Shear loads up to 6.4 lbs. Custom work available. Call for additional sizes. |

| E-109 | Used for a wide variety of applications, where a large degree of dampening is needed. |

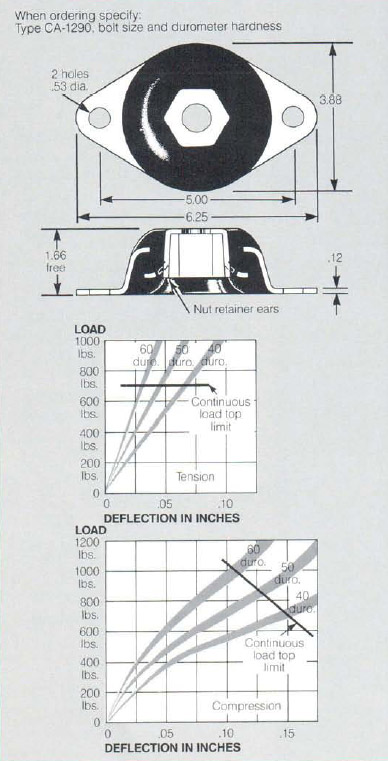

| CA-1595 | Engine mounting, air conditioning. Machinery mounting 200lbs-800lbs. Capacity nut retainer, ear holes .53” dia. 1/2” dia. center hole shown. |

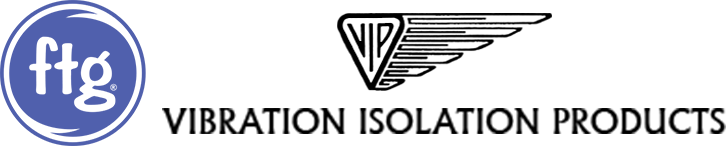

| CA-1290 | Engine mounting, air conditioning, machinery mounting can be used in tandem to isolate vibration in compression and shear conditions. Available with 1/3”, 5/8”, or 3/4” bore only. |

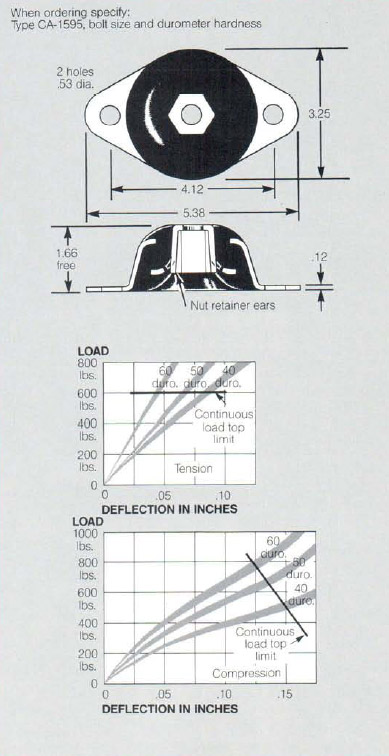

| CA-244 no.5, no.7 | Light compressive loads in the range of 100 to 400 lbs. Machinery mounting. Engine mounts used where applicable. No.5 has 1/2”-20 S.A.E. thread. No.7 has 3/8-16 S.A.E. thread. |

| 11M15, 25, 50 | Used for military applications. Durable and light. Compressive loads, HVAC, compressors. Call for specs and other application usage. |

| VIP8692656 | Plate mount used for lightweight applications. Loads up to 25lbs when used in conjunction. Up to 50lbs. Call for specs. |

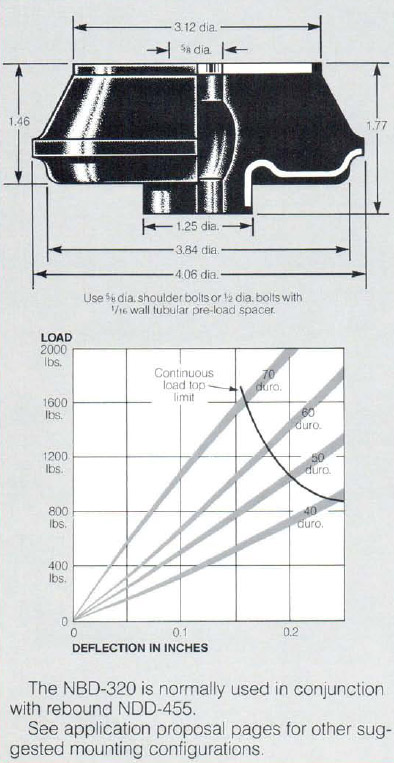

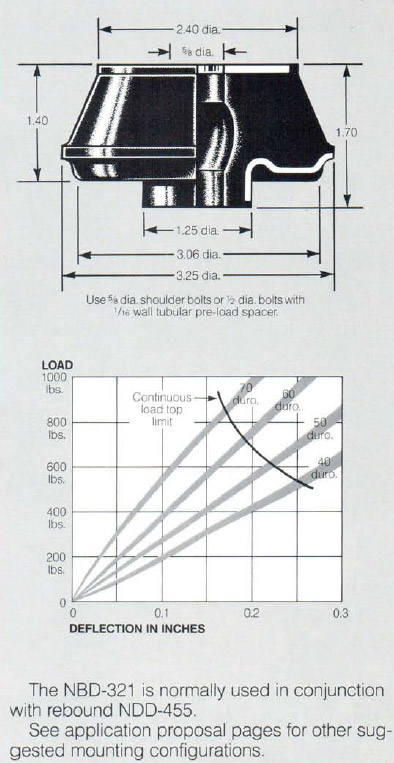

| NBD320, 321 | Vibration dampener, machinery mount. Engine mount NBD 320 is normally used with rebound NDD-455. Loads up to 1600lbs. 321 up to 800lbs. .781” center hole diameter. 40,50,60,70shore available. |

| NDD455, 456 | Engine mount. Compressors can be used in conjunction with the NBD320, 321, or by itself as a primary mount. Loads up to 400lbs. NDD455 has a .62” center hole diameter. NDD456 has a .90” center hole diameter. 40,50,60,70shore available. |

| VIP100-24SQ | Lightweight mounts. HVAC compressors light loads up to 5lbs. In conjunction up to 40 lbs. .20” center holediameter. |

| CA368 no.6 thru 8 | Motor isolators used for machinery mounting. Radiators, air compressors up to 200 lbs. Isolates nearby systems from motor vibration. .62” center hole diameter. 40,50,60,70shore available. Use of DA993 metal cup is recommended. |

| S7400-3 | Machinery mount. Heavy duty application, call for specs. |

| CA368 1 thru 5 | Motor isolators used for machinery mounting. Radiators, air compressors up to 200 lbs. Isolates nearby systems from motor vibration. .62” center hole diameter. 40,50,60,70shore available. Use of DA993 metal cup is recommended. |

| 1163302-04 | Ideal for mounting heavy loads that need severe vibration isolation. Engine suspension, machine mounts. Can be used as a bumper as well. 1163302-04 has 3/8″x24 threaded studs. |

| CM1000; CM2000 | Cup mounts have goodshock &vibration isolation characteristics at freq. above 40Hz. Can be mounted in any direction for protection of electrical& mechanical equipment. CMJ1000 1/4”x20 center hole 140lbs max load. CM2000 3/8”x16 center hole 250lbs max load. |

| A CA244-7-60; B VIP117-645-0 | Lightweight mounts 2-5lbs. Computers, refrigeration, compressors, electrical motors, bushing, lightweight applications. Call for more info. |

| K93501-15 | This shear mount can be used for engines, transmissions, machinery…Threaded studs are 3.625” apart. Through holes are 7/16” dia. |

| 10870335 | Resilient mount. Can be used for a wide range of applications. Loads either vertically or horizontally. Nominal axial load of 1,240lbs. Custom rubber formulations will allow for endless possibilities. 1.125” center hole diameter. |

| DA993 | Metal cup was designed for use with CA-368 mount. Employed to help separate the mounts and rebounds. |

| SEW22181 | Rubber coated bushing for head pulley. Call for more information on application. |

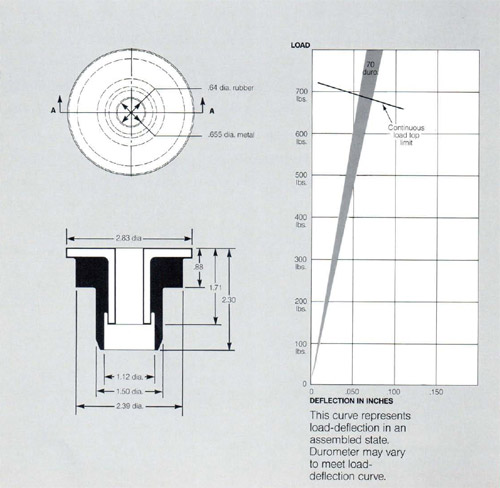

| NBD6310 | Firestone insulation, engine mount, machinery mount, radiators. Vehicle cabs both on and off road. Up to 700lb. Load deflection is adjustable with rubber hardness to meet your requirements. Call for info. |

| Cushion Bumpers | VIP offers a wide variety of bumpers (as shown).The 4 pictured are our most popular design, loads up to 250lbs. Flat nose, snub nose, and standard bumper style. |

| VIP50074-11 | Center bolt mount. Lightweight, 60lbsload for a variety of applications. Call for more information. |

| VIP-117-645-0 | Pipe grommet, used for protection of metal tubing. Different sizes available, call for more info |

| VIP80-0150; 80-130; 80-131; VIP40-0150; 20-0130 | VIP manufactures a few sizes of pipe/pressure vessel saddles to aid in cushioning your piping from surrounding vibration. For sizes in stock, please call. |

| M2318-07; M2319-07 | Fluted sleeve used for panel applications. |

| 1CRE622 thru 6CRE622 | Rubber grommet for tube cable pressure seal use and panel through hole applications as well. |

In 1991 Vibration Isolation Products, Inc. purchased the Firestone/Bridgestone product line of industrial machinery mounts. You may find our entire product line of the Firestone Mounts listed below. Please contact us if you have any additional questions about our products.

CA-1290 Large Machinery Mount

1. Ease of installaion -the underside of the centerinsert is a socket adapted to receive a standard hexagon nut, and is provided with two ears which can be bent over with a cold chisel to retain the nut in place, thereby allowing the machine to be placed on the mounting and a bolt or cap screw inserted from the top.

2. Factor of safety – the telescopic inserts provide considerable stability in all directions in ahorizontal plane. Also, because of the vertically interlocking flanges, a factor of safety is provided such that unforeseen dynamic forces or complete disintegration of the rubber by fire etc, will not permit the machine to topple from its foundation.

CA-1595 Medium Machinery Mount

1. Ease of installaion -the underside of the centerinsert is a socket adapted to receive a standard hexagon nut, and is provided with two ears which can be bent over with a cold chisel to retain the nut in place, thereby allowing the machine to be placed on the mounting and a bolt or cap screw inserted from the top.

2. Factor of safety – the telescopic inserts provide considerable stability in all directions in ahorizontal plane. Also, because of the vertically interlocking flanges, a factor of safety is provided such that unforeseen dynamic forces or complete disintegration of the rubber by fire etc, will not permit the machine to topple from its foundation.

CA-244-5 & -7 Small Machinery Mount

The mounting is small, compact and easy to install. It can be fastened to the floor, or other base, with bolts through the two ears of the metal stamping. The machine to be isolated may be set directly on the mountings and fastened to them by screwing a 1/2 bolt directly into the upper metal insert of the mounting.

NDB-320 Large Multi-purpose Mount

NBD-321 Medium Multi-purpose Mount

CA-368 -1, -2 & -3 Machinery Mounts

These mounting should be used ina manner similar to the typical installations as depicted on sheet titled “Application of Type CA-368 Machinery Mountings.”They may be used in conjunction with rebound mountings type CA-368 No.6, 7, or 8 in pairs, or in combination with any CA-368 mounting. This unit resticts the free movement of the machine to be isolated, to some extent, which is very desireable in some installations.

Care must be taken when making any installation to see that the nut is not drawn too tightly as this would put too much pre-compression on both the mounting and the rebound unit, and, as a result, the set-up wilnot function properly. The use of a shoulder bolt is desirable to prevent an excess of inital compression.

Use of metal cup DA-993 recommended.

CA-368 -6, -7 & -8 Machinery Rebounds

These units were specifically designed to be used in conjunction with the CA-368 No. 1,2,3 or 5 mountings as depicted on the sheet titled “Application of Type CA-368 Machinery Mountings.”The rebound unit is used to limit the movement of the machine on the rebound which is caused by the shock or vibration. Care must be taken when making any installation to see that the nut is not drawn too tightly as this would put too much pre-compression on both the mounting and the rebound unit, and, as a result, the set up will not function properly.

In certain instances it might be desirable to use the rebound unit itself as a mountiing or vibration dampener. ( This application is also shown on the sheet titled “Application of Type CA-368 Machinery Mountings”).

Use of metal cup DA-993 recommeded.

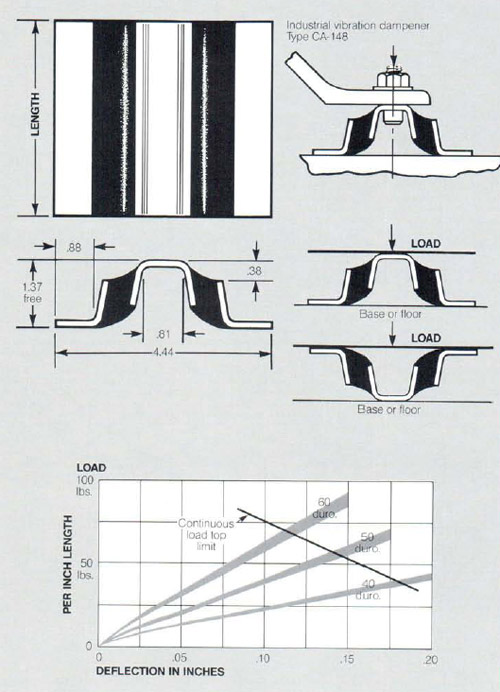

CA-148 Motor Mount

Other lengths can be furnished on special order.

Shown are two suggested methods of installation of this mounting.

Selection of the proper length for a given durometer hardness may be quickly made from the table.

NBD-6310 Isolator

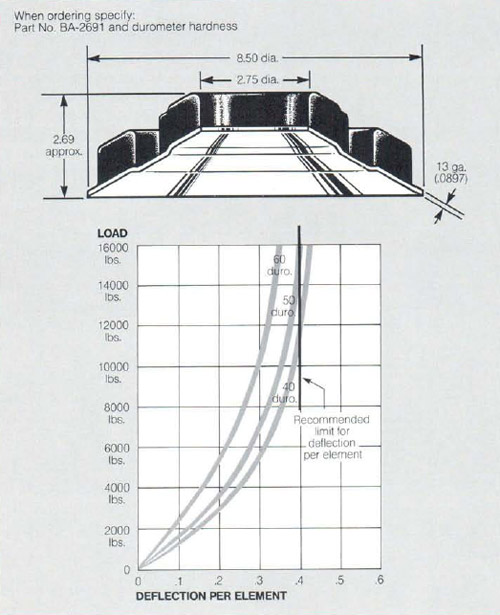

BA-2691 Heavy Duty Spring Disk

These discs may be stacked one on the other in order to obtain the length of spring and the deflection which is desired. When used in this manner, the vertical height of each disc is approximately 11/8″ when unloaded. A center rod may be used for stability if needed.

Where a stack preload is provided by a bolt, or rod passing through the center of the stack a maximum rod diameter of 1.75 diameter is recommended. This clearence is required to prevent interference due to rubber distortion under high peak loads.

These spring discs are not carried in stock but can be manufactured to order in the durometer hardness specified.

| Products | Part # | Description |

|---|---|---|

| 1163302-04 | Ideal for mounting heavy loads that need severe vibration isolation. Engine suspension, machine mounts. Can be used as a bumper as well. 1163302-04 has 3/8″x24 threaded studs. |

| K93501-15 | This shear mount can be used for engines, transmissions, machinery…Threaded studs are 3.625” apart. Through holes are 7/16” dia. |

NSN List

| 5325-01-024-3473 | 5330-00-157-6585 | 5330-00-715-3869 |

| 5330-01-106-8022 | 5330-01-124-9314 | 5330-01-125-4269 |

| 5340-00-479-4567 | 5340-00-689-7213 | 5340-01-115-8971 |

| 5342-00-071-2797 | 5342-00-500-5787 | 5342-00-530-8810 |

| 5342-00-543-3574 | 5342-00-598-8824 | 5342-00-598-8825 |

| 5342-00-664-3276 | 5342-00-664-4473 | 5342-00-678-3532 |

| 5342-00-678-4765 | 5342-00-678-5389 | 5342-00-687-5684 |

| 5342-00-725-3547 | 5342-00-738-4659 | 5342-00-753-8640 |

| 5342-00-762-6434 | 5342-00-905-1679 | 5342-00-966-7007 |

| 5342-01-020-5071 | 5342-01-020-5589 | 5342-01-230-2030 |

| 5342-01-267-8474 | 5342-01-272-7822 | 5342-01-438-8442 |